What is an IQF Tunnel or Quick Freezing System?

Frozen foods have very high quality and nutritional value. Contrary to popular belief, the taste and flavor of some vegetables such as peas and sweet corn may be better when frozen than when fresh. Of course, the method of freezing and the conditions under which it is frozen have a significant impact on the final quality. Today, high-quality freezing is often achieved using a quick freezing system.

Individual Quick Freezing, which is also known as IQF for short, is a system that does not allow large ice crystals to form. Also, in this method, since each component is frozen independently, the ice particles do not stick together and the final product will not be a solid block.

The working method of IQF tunnels was discovered by a Canadian biologist who was fishing in a frozen lake. He realized that if he immediately threw the caught fish on the snow, the fish would freeze quickly.

The interesting point was that some of the fish that were frozen in this way were surprisingly alive after being thawed, which shows the high quality of this freezing method. The result is that a substance that freezes faster creates smaller ice crystals within it.

Large ice crystals damage cells and tissues, but small crystals do not have this effect. IQF tunnels are also designed on this basis so that by very quickly freezing food, the crystals formed are smaller and do not damage the food.

In addition to the mentioned materials, IQF tunnels also cause fewer crystals to form. Most of the crystals formed in food occur between 0 and -4 degrees Celsius.

The longer a substance remains in this temperature range, the more crystals will form. The key point of IQF tunnels is also to maximize the speed of temperature reduction in this temperature range.

For example, a package of fish in the refrigerator takes about 10 hours to freeze, but this can be done in 90 minutes in IQF tunnels. The time that this package remains in the crystal formation temperature range is 6 hours in the refrigerator, but only 25 minutes in the IQF tunnel.

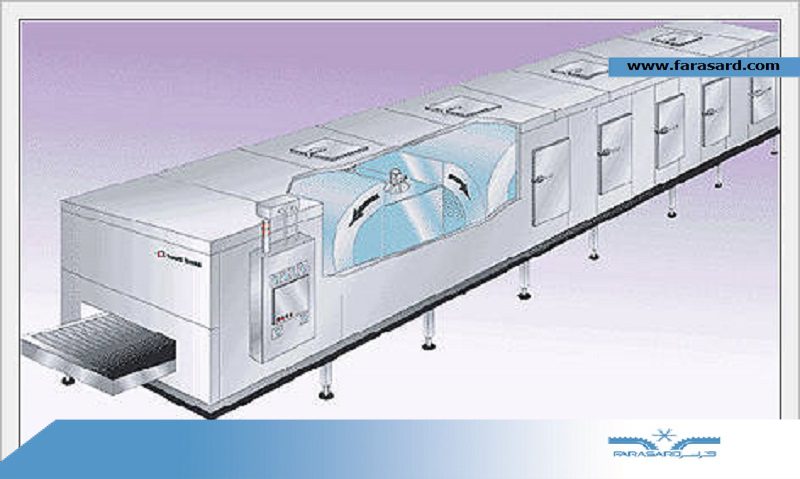

Types of IQF Tunnels and Their Design

Due to the novelty of IQF tunnel technology, different companies have created and implemented different designs in this field. Among the designs used in various industries, three freezing methods are most commonly used: Fluidized Bed Freezing, Cryogenic Freezing, and Plate Freezing. We will discuss them in more detail below.

Among these three methods, fluidized bed freezing and cryogenic freezing are classified as direct freezing methods, while plate freezing is considered an indirect freezing method.

Fluidized Bed Freezing

High rates of industrial and commercial freezing can be achieved by introducing the product into an insulated tunnel with a strong flow of cold air. In the fluidized bed freezing method, food pieces are fed into this tunnel using trays or belts.

The food is fluidized (meaning converted into a bed of small particles) and then cold air is forced through and between them, freezing the food. The cold air temperature is usually between -18°C and -34°C, and the air speed is around 2 to 5 meters per second to increase the heat transfer coefficient.

Since this method allows the construction of IQF tunnels in various sizes and shapes, it is considered an economical method.

The thickness of the food particles entering the tunnel depends on their type. For example, food can be frozen in sizes ranging from peas to strawberries with a thickness of 1 to 5 inches, while products such as green beans can be frozen with a thickness of 8 to 10 inches.

Cryogenic Freezing

For some products such as tomatoes, mushrooms, and strawberries, the freezing time needs to be very short, which is only possible by immersing them in liquid nitrogen or liquid carbon dioxide at a low temperature (below -60°C) to quickly freeze the outer layer of the product.

Plate Freezing

The plate freezing method is considered an indirect freezing method because there is no direct contact between the freezing fluid and the frozen product. In this method, the food products are in contact with metal plates that are indirectly cooled using chilled brine or other refrigerants.

This process is suitable for freezing products such as shrimp. The plate freezing is very economical because it minimizes dehydration problems, ice crystal formation, and bumps in the final product.

Advantages of Using IQF Tunnels

Preservation of Quality and Nutritional Value

The preservation of food quality was discussed in previous sections, and in fact, this is the most important goal of using IQF tunnels.

Cost-Effectiveness

The frozen final product is cheaper than fresh products in the market in many cases. This can also be suitable for restaurants and food distributors; as they can buy food in bulk and use it while maintaining quality.

Availability of Various Food Products in All Seasons

Considering that it is very difficult to find some food items in each season and their prices will be high, it is possible to have access to a high-quality product in each season by freezing them in IQF tunnels.

Factors Affecting the Price of IQF Tunnels

Due to the higher technology of IQF tunnels compared to conventional freezing tunnels, the price of these devices is also higher. In addition to advanced technology, these tunnels should provide a lot of cold in a short time, and for this reason, the capacity of different parts of these tunnels is more than conventional tunnels, and consequently, their price will be higher.

The most important factor affecting the price of a freezing tunnel is its capacity. The higher the capacity of a freezing tunnel and the amount of material that needs to be frozen, the higher the rate of cold generation and, consequently, the larger the refrigeration system equipment will be. In addition to system capacity, factors such as control method, equipment quality, type of frozen food, and type of refrigeration system determine the final price of an IQF tunnel.

Applications of IQF Systems

Any type of food can be frozen in IQF tunnels. The most common types of food frozen in these tunnels include vegetables and fruits such as blueberries, plums, raspberries, strawberries, shrimp shells, and various red and white meats.

Conclusion

Farasard, with several decades of experience in various refrigeration systems, is ready to provide consulting regarding IQF tunnels. Choosing an IQF tunnel for a specific application is a complex process that requires engineering knowledge and experience in this field.

To get information about IQF systems and choose an IQF tunnel suitable for your application, please contact our experts. Farasard is ready to design and manufacture all types of IQF tunnels with up-to-date technology for you.