Pharmaceutical and Chemical Chiller

- Designed and manufactured by Farasard

- High reliability due to product temperature sensitivity

- Available in a variety of cooling capacities

A pharmaceutical and chemical chiller is a device used to provide the required temperature in the pharmaceutical and chemical industries. The most common type is the compression chiller.

These chillers can accurately control temperature and are highly reliable. In the pharmaceutical industry, many materials and liquids must be kept at a specific temperature during production to ensure that chemical and physical processes are carried out completely and without problems.

Understanding Pharmaceutical and Chemical Chillers

Many chemical reactions are exothermic and require the final product to be cooled after the reaction is complete. Some pharmaceutical and chemical products must also be delivered at a low temperature to be prepared for storage or market.

Almost all medicines require cold water during the production process. Therefore, temperature control is one of the main requirements in the pharmaceutical and chemical industries to achieve a high-quality final product.

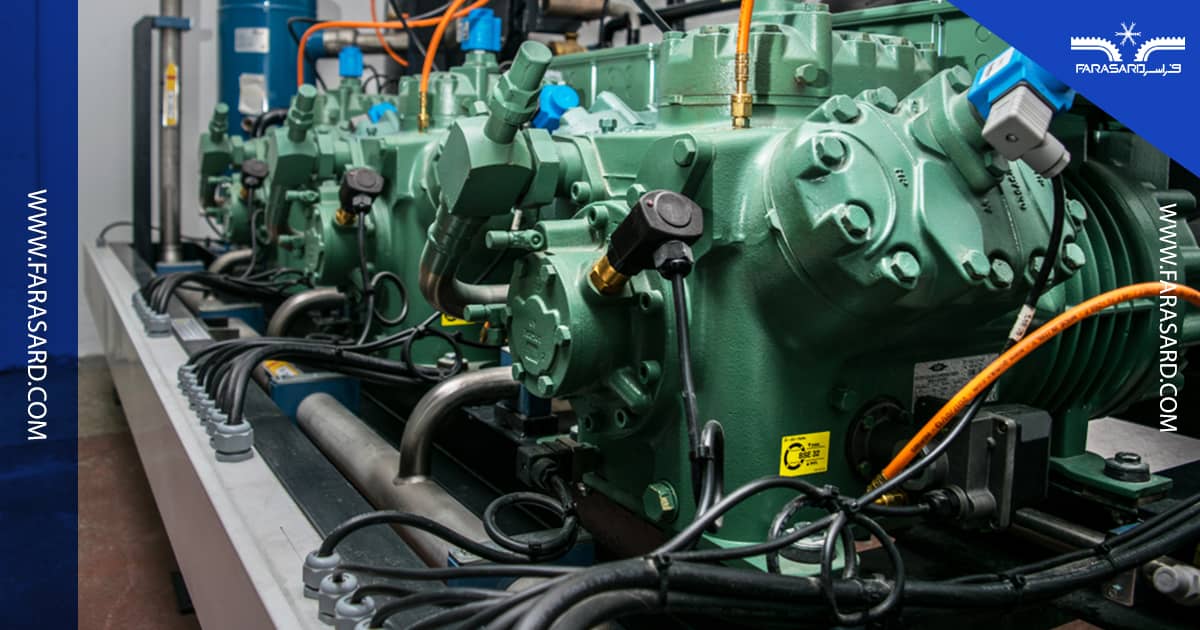

Farasard manufactures pharmaceutical and chemical chillers with three types of evaporators, each with its own characteristics. The first type is shell and tube evaporators, which take up a lot of space but are less expensive than other models.

The second type is plate evaporators, which have a more compact design and can exchange a lot of heat in a small space. The third type is welded plate evaporators, which can withstand higher temperatures and pressures due to their strong connections and offer the best performance.

Two types of chillers are used in pharmaceutical and chemical companies. The first type is for companies that manufacture pharmaceutical and chemical containers and molds in-house and therefore also require industrial chillers to cool these molds. These chillers are similar to plastic injection chillers. In the second type, the containers and molds are purchased from outside and only chillers are needed to cool the products and liquids in the pharmaceutical and chemical production processes.

In pharmaceutical applications, chillers with low and medium capacities can meet the user’s needs, given the small amount of product produced. In these applications, air-cooled chillers can be used for ease of use and cost savings.

In contrast, chemical plants use the maximum capacity of their lines to achieve the highest possible production. Therefore, the chillers required in these applications are medium and high capacity chillers.

Also, if the capacity is high and water is abundant, it is recommended to use water-cooled chillers with a cooling tower. Another point to consider when using industrial chillers for chemical applications is the suitability of the evaporator heat exchanger for chemical fluids, which may be highly corrosive.

Price of Pharmaceutical and Chemical Chillers

The price and total cost of a pharmaceutical and chemical chiller depends on many factors, the most important of which is the chiller capacity, which is usually expressed in tons.

The capacity of the chiller determines not only the size of the different components but also their type. For example, air-cooled condensers can dissipate the heat of chillers with low capacities, but evaporative or water-cooled condensers are required if the capacity is high.

In addition to the chiller capacity, the type of condenser and evaporator heat exchangers and the type of compressor are also factors that affect the price of a chiller. Special considerations for pharmaceutical and chemical applications, including chiller stability and the suitability of the evaporator heat exchanger for contact with pharmaceutical and chemical materials, are other factors that are unique to this application.

Conclusion

Farasard has extensive experience in the manufacture of industrial chemical and pharmaceutical chillers. For consultation and selection of the right chiller for your application, please contact Farasard experts.