Chiller for Plastic Injection Machines

- Waste Reduction

- Higher heat transfer rate, less maintenance

- Equipment protection

- Increased production

Applications of Chillers for Plastic Injection Machines

First, we will explain the application of chillers for plastic injection machines, and then we will discuss the advantages and specifications of plastic injection chillers. Injection molding machines or plastic injection machines are widely used to produce various plastic parts.

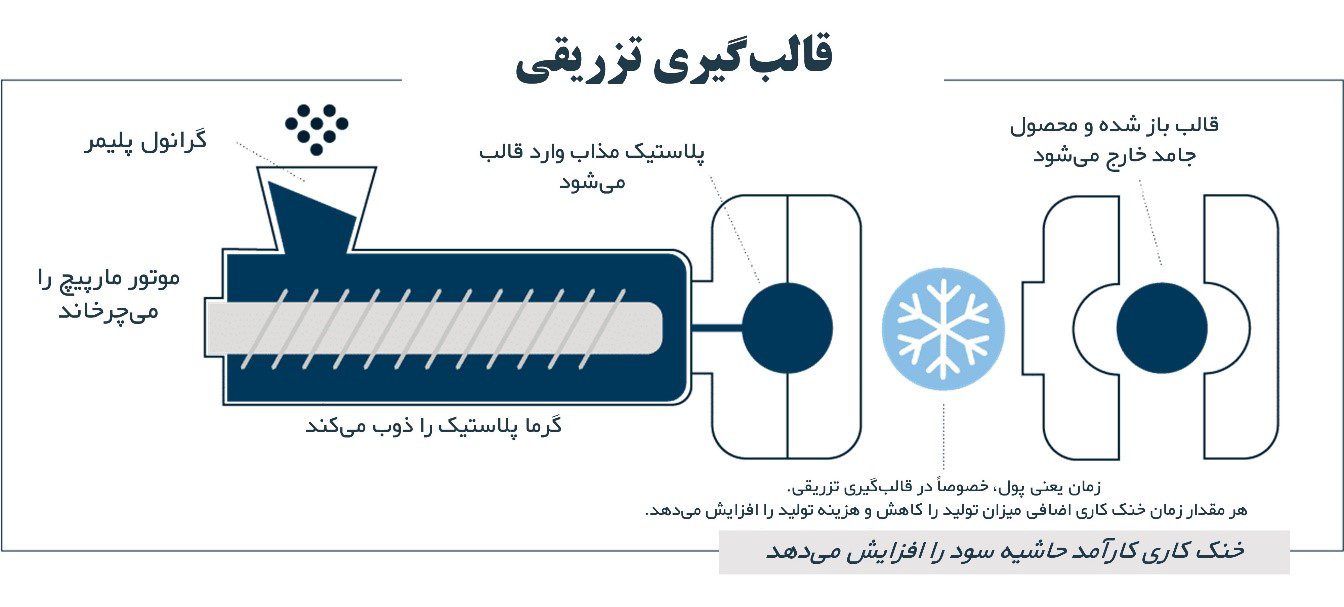

The injection molding process is a process that is used for the mass production of parts that are to be produced in thousands or even millions of copies. In this method, the molten plastic material is injected into the cavity of an injection mold. Then the molten material gradually cools and hardens inside the mold and takes the shape of the mold cavity.

The cooling stage of the part is before it is removed from the mold, and therefore the chiller for plastic injection machines is very important in this process and can affect the quantity and quality of production.

If the mold is filled and then cooled too quickly, the quality of the part will be severely affected; and if the cooling stage is too long, the production speed will decrease and the production cost will increase.

In the plastic injection system, the mold actually acts as a heat exchanger, in that it first transfers heat from the molten plastic to the mold and then to the cooling medium (cold water) that is circulating in the machine. Of course, a small part of this heat is also absorbed by the machine body and the air.

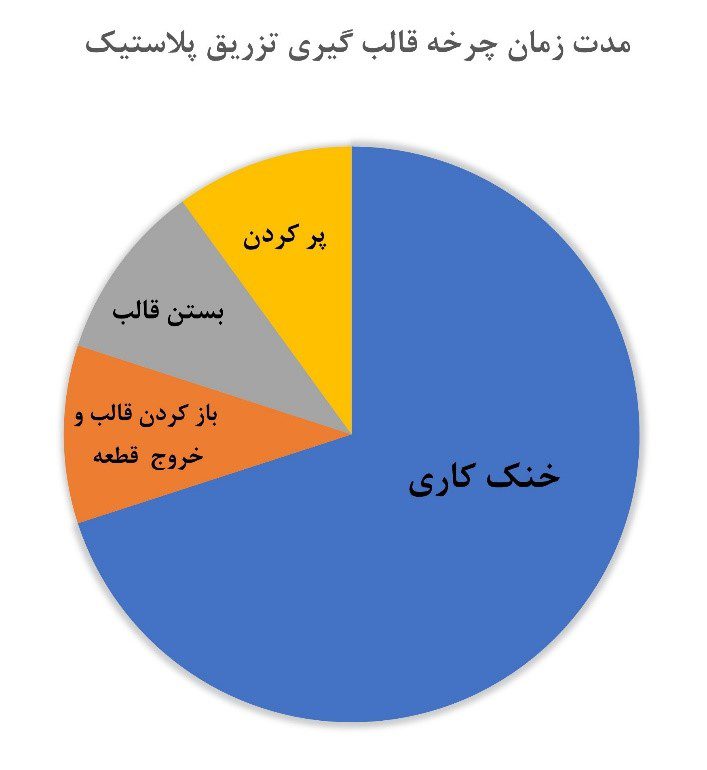

A significant portion of the injection molding cycle time (sometimes over 80% of the time) is spent on the cooling stage; therefore, it cannot be easily overlooked and the benefits that can be achieved by reducing the time of this stage cannot be ignored.

Therefore, it is absolutely necessary to minimize the cooling time, and this is possible with the use of a plastic injection chiller. The role of the chiller in this process is to produce cold water using a thermodynamic refrigeration cycle (similar to a refrigerator).

Cold water accelerates the cooling stage in the plastic injection molding process.

For example, the cycle time of a 20-second mold that uses cooling tower water for cooling can be reduced to 16 seconds using a plastic injection chiller. Although this change requires a higher initial cost, it can be very profitable in the long run due to the 20% increase in production.

Reasons for Using a Chiller for Plastic Injection Machines

There are two general reasons for using a plastic injection chiller in molding:

- Equipment protection The cost of a chiller is lower than that of other process equipment, but it can be very effective in protecting the equipment and the investment made in it.

- Increased production Maintaining a constant and appropriate cooling temperature in the process equipment can increase the number of parts produced per hour and significantly reduce the number of defective parts.

Advantages of using a chiller in a plastic injection machine

The advantages of using a chiller for cooling in the injection molding process are:

- Reduced waste: Consistent and reliable provision of the appropriate temperature for the process leads to a reduction in waste and defective products.

- Higher heat transfer rate, less maintenance: The water discharged from the chiller circulates in a closed loop and is therefore of good quality. This results in better heat transfer, reduced maintenance requirements, and consequently reduced downtime of the machine.

- Colder water: Compared to other available cooling options, the chiller can produce much colder water.

The required cooling capacity of a plastic injection machine chiller

The required cooling capacity of a chiller for a plastic injection unit is calculated using the following formula: Q=MxCx∆TxS

In this equation,(kcal/hr) is the required cooling capacity,(kg/hr) is the weight of plastic produced per hour,(kcal/kg°C) is the specific heat capacity of the plastic and(°C) is the temperature difference between the molten material and the temperature at which the product is removed from the mold. For many common plastic products, the temperature difference oris around 200 degrees Celsius.

Also in the above equation,is the safety factor (usually between 1.35 and 2), and the value considered for it is determined depending on the distance between the chiller and the machine, the insulation of the pipes, the ambient temperature, and the operating conditions of the system.

When a chiller is used for a plastic injection machine, a smaller safety factor can be used, and if a chiller is to be used to cool multiple machines, a larger safety factor should be applied.

In most cases, in a plastic injection system, the mold is not the only part that needs cooling, and there are other auxiliary equipment in the machine that also need to be cooled to increase the operating cycle of the machine. These auxiliary equipment and a quick way to calculate their additional cooling load are:

- Hydraulic motor: 0.1 tons of refrigeration per horsepower of motor power

- Feed Throat: 0.5 tons of refrigeration

- Temperature Controller (TCU): 0.2 tons of refrigeration per horsepower of pump power

- Hot Runner: 0.15 tons of refrigeration per kilowatt of power

- Dryer: According to the dryer manufacturer’s recommendations

Specifications of a suitable chiller for a plastic injection machine

In addition to the cooling capacity, which is the most important characteristic in choosing a suitable chiller for plastic injection machines, other specifications must also be considered when choosing:

- Type of chiller: Industrial chillers are manufactured in various types (absorption/compression, air-cooled/water-cooled). Air-cooled chillers are more commonly used in plastic injection machines.

- Portability

- Compressor noise level: Chillers with reciprocating compressors are much noisier than chillers with centrifugal, scroll, etc. compressors.

- Temperature range flexibility: The plastic cooling process depends on various factors such as the size and thickness of the part, the type of plastic, and so on. Installing a chiller with the ability to create different temperatures will expand the production capability of the industrial unit.

- Precise temperature control

- Customizability

- Cooling fluid: The type of cooling fluid that enters the mold and removes heat affects the performance of the chiller. Fluids such as water/glycol solution perform heat transfer better than pure water.

- Price of the plastic injection machine chiller: The price of a plastic injection machine chiller depends on the cooling capacity, auxiliary equipment, build quality, and the factors mentioned above, many of which are determined according to the buyer’s needs.

Cooling water temperature and flow rate

The temperature of the cooling water used in the part cooling stage generally depends on the type of material and the shape of the product. For example, the required cooling water temperature for the production of thin-walled polyester containers is usually below zero degrees Celsius, but in other cases, the required cooling water temperature is above 5 degrees Celsius.

In many cases, a temperature difference of 3-5 degrees between the inlet and outlet water of the device is ideal, but sometimes a smaller temperature difference (1-2 degrees Celsius) will be required.

The amount of change in the water temperature by passing through the mold also affects the required water flow rate, so that for a given cooling load, the smaller the difference in water temperature at the inlet and outlet of the mold, the more water flow will be required.

For example, if the required flow rate in the 5-degree temperature difference case is 100 L/min, the required flow rate for the 2-degree Celsius temperature difference will be 250 L/min.

Water quality

The best pH value for cooling water used in plastic injection machines is 7. Higher pH values cause corrosion in the machine. In addition, if no action is taken to improve the water quality, the evaporator and mold will become clogged.

These deposits act as an insulator and reduce the heat transfer rate. As a result, the performance of the plastic injection chiller and cooling capacity will decrease; Therefore, to protect equipment and system performance, it is necessary to treat the water used in the cooling cycle.

The most effective measure is to install a water softener that can be installed directly in the circulating water line. Another measure can be to add scale inhibitors to the water at regular intervals.

On the other hand, if the cooling water temperature is lower than a certain level, glycol must be added to it to prevent freezing. According to the table below, the percentage of glycol dissolved in water is determined based on the temperature of the cooling fluid (solution) at the outlet of the plastic injection machine chiller.

|

Outlet water temperature from the chiller (°C) |

Recommended glycol percentage to prevent freezing of cooling water | |

| Propylene glycol % | Ethylene glycol % | |

| Above 4.5 | 0 | 0 |

| 4.5 | 20 | 15 |

| 1.5 | 25 | 20 |

| -1 | 35 | 30 |

| -4 | 40 | 35 |

| -6.5 | 45 | 40 |

| Below -6.5 |

Consult the Manufacturer |

Insulation of cooling water pipes

The pipes that transfer cooling water from the chiller to the plastic injection machine must be well insulated. This, in addition to preventing the loss of the cooling capacity of the system, prevents the formation of water droplets (due to condensation of air humidity) on the outer walls of the pipes.

Conclusion

Farasard has extensive experience in the manufacture of plastic injection machine chillers. For consultation and selection of the right chiller for your application, contact Farasard experts.