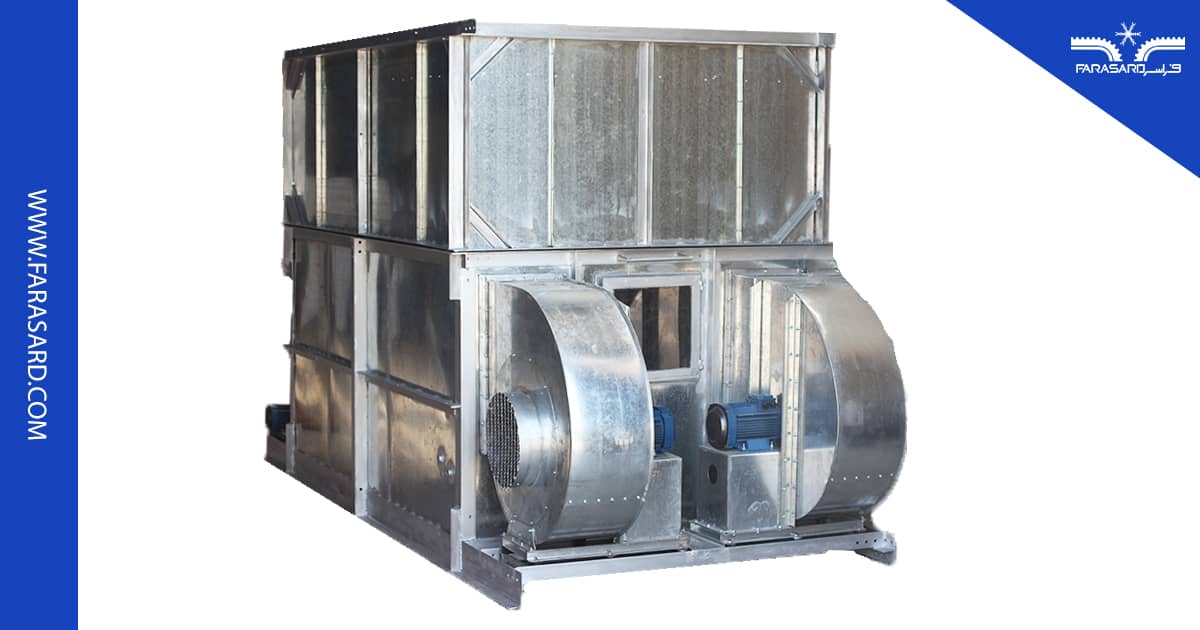

Cooling Tower | Cooling Tower Design and Manufacturing

- Production in various capacities by Farasard

- High quality parts

- Cost-effectiveness in projects

- High efficiency and performance

- Low energy consumption

- Warranty on the quality of parts

What is a cooling tower?

A cooling tower is a special type of heat exchanger in which air and water come into direct contact with each other. The purpose of this process is to lower the water temperature. Also during this process, a small amount of water evaporates, and due to the heat-absorbing nature of the evaporation process, the water temperature decreases further.

The water receives the heat of the refrigerant inside the refrigeration cycle in the condenser and is heated, and then it is pumped to the cooling tower. In such a way that the water is pumped to the top of the cooling tower and then sprayed onto the packings by nozzles and turns into small water droplets.

In addition, by using obstacles that are placed in the path of water, an attempt is made to reduce the speed of water as much as possible so that there is more time for heat exchange between water and air.

There are different architectures and structures for cooling towers. In one of the most common designs, air is drawn into the tower from the bottom by fans, and the air and water flow in opposite directions. After the heat exchange between water and air is completed, the cooled water is collected at the bottom of the tower and returned to the condenser to absorb the heat of the refrigerant.

It should be noted that cooling towers have the highest heat transfer rate and therefore can respond to cycles with very high capacities. Also, in environments with low air humidity, high efficiency can be expected from cooling towers. On the other hand, this method requires more additional equipment. In addition, if the air humidity is high, the efficiency of cooling towers drops significantly.

Components and Design of a Cooling Tower

Cooling towers are typically among the devices on which each company implements its own specific technologies and produces a unique product. These systems are made completely custom, but they are almost all made up of the same parts in all projects, which we will discuss below.

Air Louvers

Air inlet louvers are part of the cooling tower that is designed to prevent water from exiting the tower and contaminants from entering it. They also prevent direct sunlight from entering and prevent the water from heating up. The main function of air louvers is to increase airflow into the tower. If the air louvers are not properly maintained, the flow of air into the tower will be problematic and the tower will not be able to function at all.

Packing

The packing or cooling tower films are the most important part of it and determine the efficiency and performance of the tower. The larger the surface area of the packing, the higher the heat transfer rate, and therefore the purpose of placing the packing is to increase the contact surface between the water and the air.

Hot Water Distribution System

This system is located on the packing and is the collection point for hot water. Due to the corrosion and decomposition of different parts of this system due to the high temperature of the water, over time the efficiency of the hot water distribution system decreases and after reaching a certain limit, this system will not be able to transfer the water to the nozzles. Therefore, this system is one of the parts that must be replaced after a certain period.

Float Valves

The float valves of the cooling tower must keep the water level inside the tower at an appropriate level. These valves are responsible for regulating the water flow rate and their proper operation can increase the lifespan of the tower. Float valves require very little maintenance and have a simple structure. The settings of these valves are different for different towers and even if the tower is operating under different conditions, these settings must be changed again.

Nozzles

The nozzles are responsible for distributing the water and turning it into small droplets. The performance of a nozzle has a significant impact on the overall efficiency of the cooling tower, and if the nozzle cannot create droplets of the right size, the heat transfer between the water and the air will not be done properly and the efficiency of the cooling tower will drop significantly.

Fan

There is no solution to bring a large amount of airflow into a cooling tower other than using a fan that is rotated by a motor. Cooling tower fans are often very noisy, but there are also models that produce less noise.

Drift Eliminators

Another main component of cooling towers is drift eliminators, which separate water droplets from the air stream inside the tower. Water droplets contain chemicals and minerals that can affect the surrounding environment. Therefore, drift eliminators prevent water from escaping from the tower. The performance of drift eliminators is very effective, such that a good drift eliminator can capture up to 99.999% of the water in the stream and prevent it from being wasted.

Gearbox

Gearboxes are used to reduce the speed of fan drive motors. The gearbox multiplies the input torque to the motor by several times, thereby increasing the cost-effectiveness of the mechanical system. Without a gearbox, the volume of the motors would increase significantly.

Piping System

The piping system is responsible for distributing water in the cooling tower and returning it to the condenser. The size and type of piping system pipes depend on the type of tower, the technical drawings of the plan, and the geographical location of the area.

Motors

The motors of a cooling tower, which are often electric, are responsible for supplying power to mechanical equipment such as fans and pumps. These motors must be efficient and capable of withstanding the harsh conditions of the cooling tower. Two types of open and closed electric motors are used in cooling towers. Open motors allow air to pass from the body into the electric motor, which allows them to have better heat exchange, but on the other hand, they are more vulnerable. In closed motors, no air can enter the body, and this type has a higher resistance to adverse environmental conditions.

Cooling Tower Pricing

Initial Cost

Making an initial estimate of the price of a cooling tower may seem easy, but in practice, it is a challenging task. Although the price estimate for most cooling tower equipment is proportional to the refrigeration system capacity, many of these equipment have different capacities for each refrigeration ton; In other words, two devices with similar functions and equal output capacity have different input power and efficiency. Therefore, it is not possible to accurately calculate how much the price of different cooling tower equipment will be for a system that has, for example, a capacity of 100 refrigeration tons, and all calculations are approximate. In the following, we will examine the factors affecting the initial cost of a cooling tower.

Installation Location

The installation location can determine the installation process and its complexity. For example, if the installation location of a cooling tower is chosen on the ground, the installation process and some of the tower systems will be simpler and access will be much easier, but installation at height requires advanced equipment. For example, in some projects, helicopters are used to install cooling towers on the top floors of towers.

Capacity

The capacity of the cooling tower determines the dimensions of the tower and the capacity of related equipment such as pumps, nozzles, fans, and electric motors, and is the most important factor that determines the price of the cooling tower.

Equipment Quality

In cooling towers, there are many equipment that are only installed on the tower and the cooling tower manufacturing companies buy these equipment and have no role in their design and manufacture. Examples of these equipment are electric motors, fans and pumps. The higher the quality of these equipment, the higher the price of the cooling tower.

Replacement or First-Time Installation

Replacing some cooling towers due to the passage of time and the decay and failure of parts is inevitable. In the event of replacing a cooling tower, additional costs are required, such as dismantling the equipment, inspecting and repairing the associated equipment, and spending more time to install the new tower, which are not incurred in the first-time installation.

Installation Type

In general, prefabricated cooling towers are considered as systems with higher efficiency and performance than systems that require assembly at the installation site.

Cooling Tower Running Costs

Maintenance and Replacement of Parts

The operation of the cooling tower is such that some of its equipment and parts will need to be replaced over time. The time interval for replacing parts and the number of parts that need to be replaced vary in different designs, but in general, proper design and part quality are among the most important factors that determine the replacement interval.

Energy Cost

Cooling towers with higher initial costs have higher efficiency and therefore lower energy consumption. Of course, there is an optimal point for all projects that should be determined according to the existing conditions and a careful review of initial and running costs.

Conclusion

Cooling towers are among the industrial equipment that are used for systems with high capacity, and their economic justification is only justified in medium and large projects. Choosing these systems, given the complexity of their operation, can be a difficult process that requires a lot of experience. Cooling towers also require a lot of care and maintenance, and if the right system is not chosen, many of their equipment and parts will be exposed to thermal and mechanical stresses and will fail in short periods. FarasardCompany, with its extensive experience in the field of refrigeration systems, is ready to provide consulting services for choosing the best cooling tower for your application. Farasardis also capable of carrying out all stages of design, construction and installation of cooling towers specifically for your application, so that with the implementation of the most optimal choice, the initial and running costs of your project are minimized.